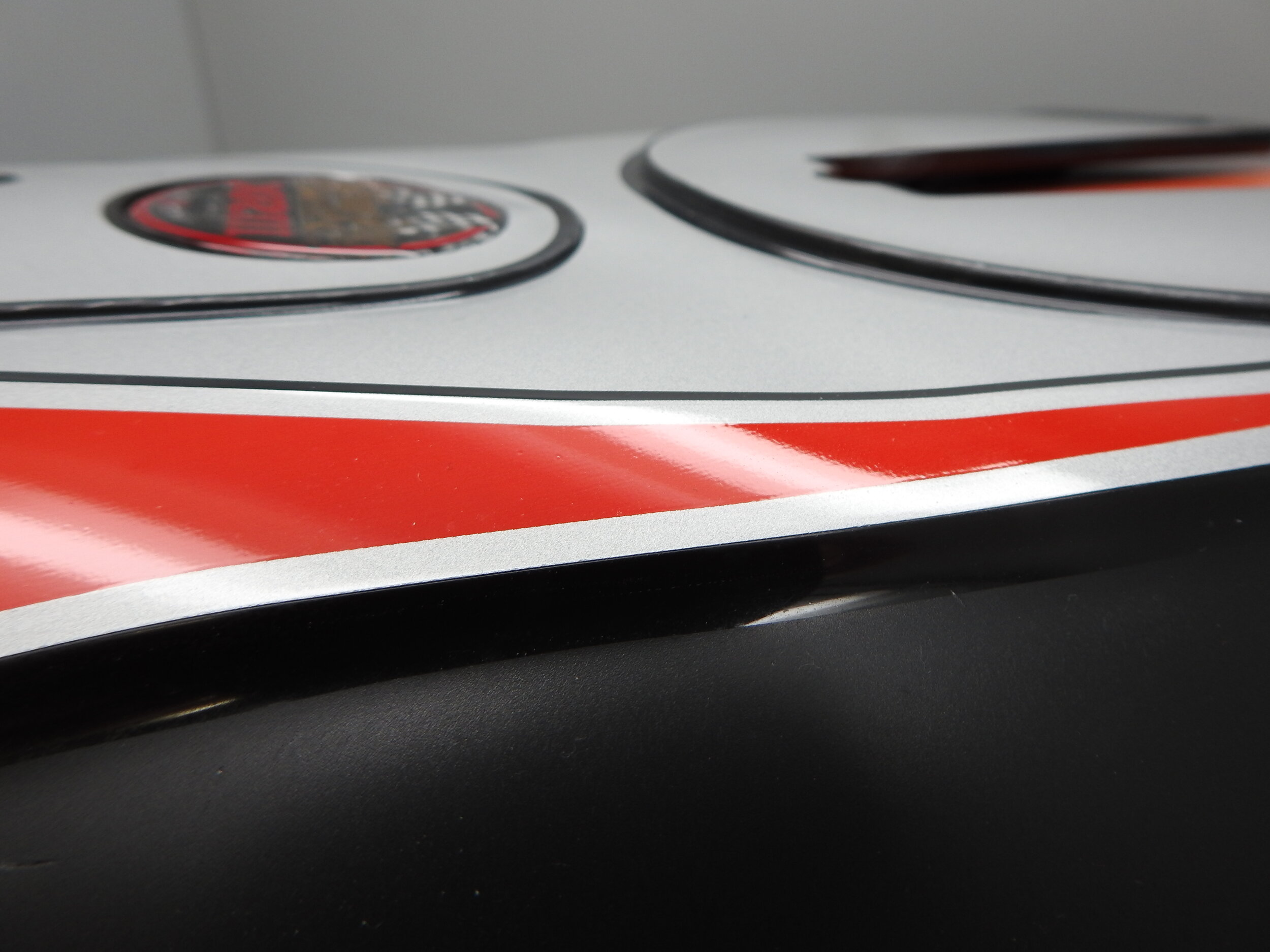

Embellish products with graphics that portrays a feeling of extravagance – without the price tag.

In-mold decals are found on everyday use plastic containers like shampoo bottles, yogurt cups and butter tubs. A unique process of decorating, in-mold has grown tremendously over 20 years. Slowly but surely it’s creeping into more durable industries that use injection molding.

The up-front investment in time and money pays off with beautiful and indestructible branding. Our most popular products are polyolefin/polypropylene based injection molded decals.

Romo has engineered our own base material, inks and coatings that bonds easily with polypropylene during the injection-molding process.

Eliminate secondary decorating like; adhesive decals, hot stamping, heat transfer and pad printing.

Automatic one-step process that decorates and mold all at once.

No label profile because the label is molded into the product. No dirt or moisture can loosen the adhesion.

Extended durability – fusing the graphic to resin means strength and durability.

Our customers mold:

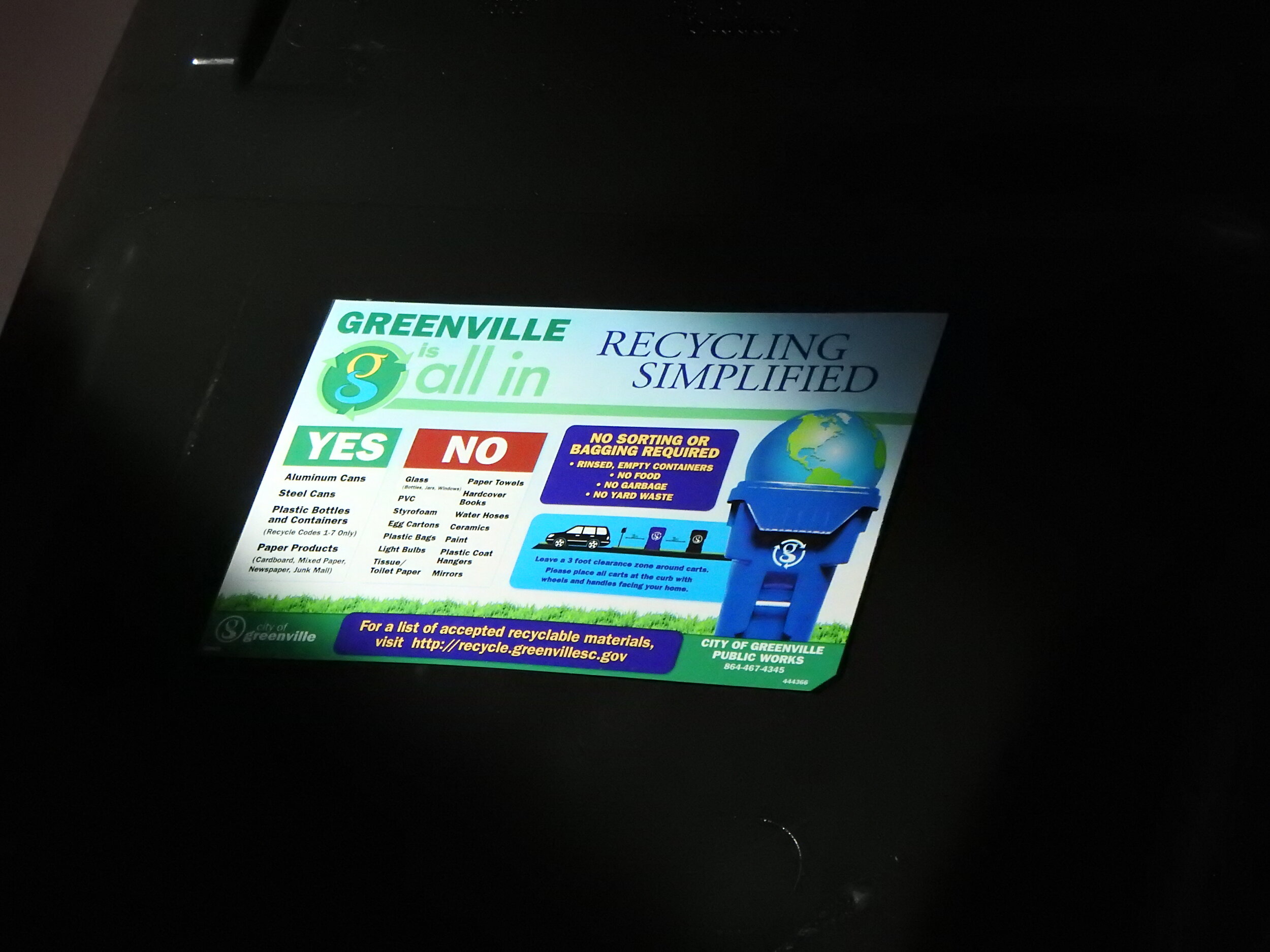

Recycling containers

Buckets and storage containers

Outdoor furniture

Lawn and garden equipment

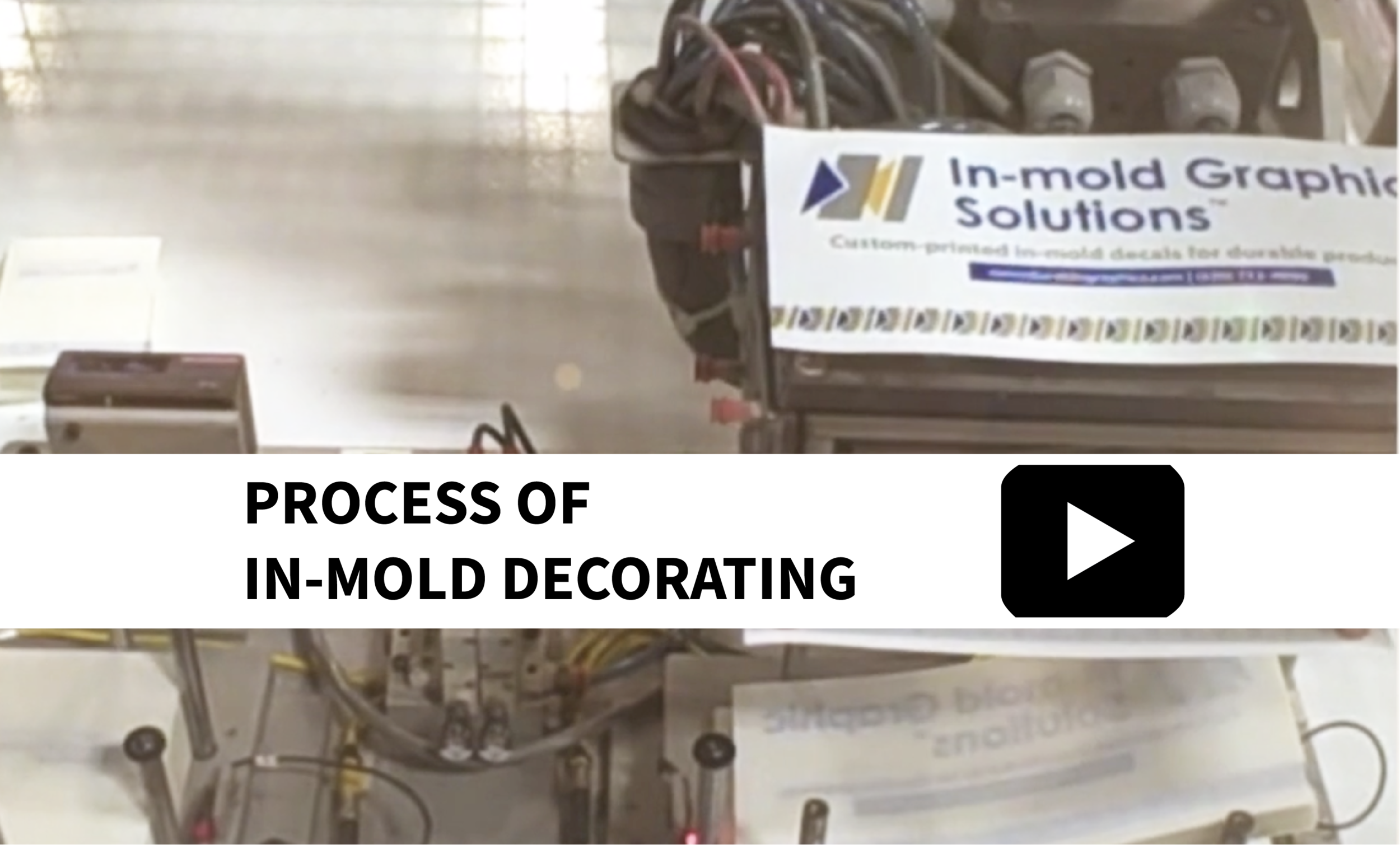

The process of in-mold decorating

A technique in which a pre-printed label is inserted into a mold before hot plastic enters it. The easiest surface to decorate is flat and therefore with flat labels it is possible to create high-quality images on plastic. Labels are printed on materials that are designed to match the plastic being molded (varying in thickness from 5 Mils to 15 Mils).

Injection molding is the largest producer but it’s also used in thermoforming and blow molding processes.

Unfortunately, Romo doesn’t have a blow molding solution yet.

The injection molding technique starts with an end-of-arm tool inserting the label into the cavity. The label is designed to take the shape of the internal surface. Vacuum holes or electrostatic charge are used to hold the label in place.

Although the IML technique is most often associated with food packaging, it is also widely used in technical products where there is a need to label or decorate the surface of a plastic part. In such applications the technique may be referred to as In-Mold Decoration (IMD).

Continue Exploring

There’s more on our blog - here are some featured related posts:

A Tupperware container made using glow in the dark ink.

The possibilities are limited only by our imagination.

Want to know how in-mold decorating happens?

Watch the process in action.

PPAP is a standardized process used to ensure each part meets expectations every time it’s produced. So how does it happen? Where do you begin?